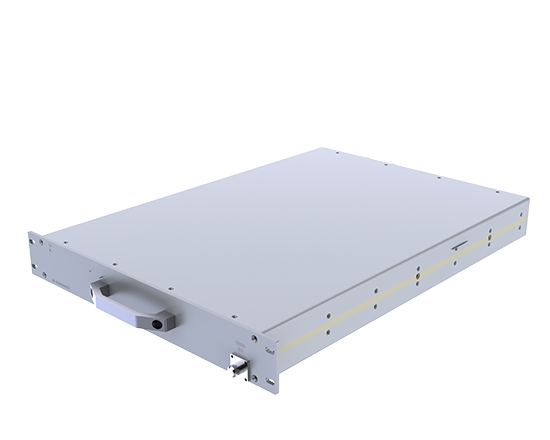

Based on its independently developed passive components, STR Laser has achieved innovative breakthroughs in pumping technology. The 2kW narrow linewidth single mode fiber laser is its a mass-produced model utilizing the innovative 976nm pumping technology and adopting modular design. Featuring compact structure, good reliability and environmental adaptability, this model meets the requirements for ultra-high power beam combination and finds wide applications in industrial, medical, aerospace, and military fields.

Handheld Laser Welders

Handheld Laser Welders Special Welding

Special Welding Additive Manufacturing Series Fiber Lasers

Additive Manufacturing Series Fiber Lasers Narrow Linewidth Single Mode Fiber Laser

Narrow Linewidth Single Mode Fiber Laser High Power Single Mode Fiber Laser

High Power Single Mode Fiber Laser Core Components

Core Components Laser Welding

Laser Welding Additive Manufacturing (3D printing)

Additive Manufacturing (3D printing) Precision Processing Equipment

Precision Processing Equipment Marketing Information

Marketing Information Cooperative agents

Cooperative agents Product manuals

Product manuals News

News Join

Join Industry knowledge

Industry knowledge Company introduction

Company introduction Development history

Development history Technology&R&D

Technology&R&D Cooperative partner

Cooperative partner Corporate culture

Corporate culture Contact us

Contact us