-

Laser Welding

Laser Welding Laser Source

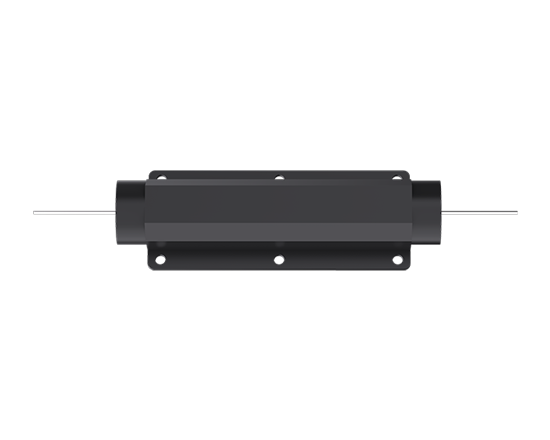

Laser Source Core Components

Core Components -

Laser Welding

Laser Welding Additive Manufacturing (3D printing)

Additive Manufacturing (3D printing) Low-Altitude Placement

Low-Altitude Placement Precision Processing Equipment

Precision Processing Equipment -

Marketing Information

Marketing Information Cooperative agents

Cooperative agents Product manuals

Product manuals -

News

News Join

Join Industry knowledge

Industry knowledge -

Company introduction

Company introduction Development history

Development history Technology&R&D

Technology&R&D Cooperative partner

Cooperative partner Corporate culture

Corporate culture Contact us

Contact us